1.Luyini uhlelo lokuphatha ibhethri le-BMS?

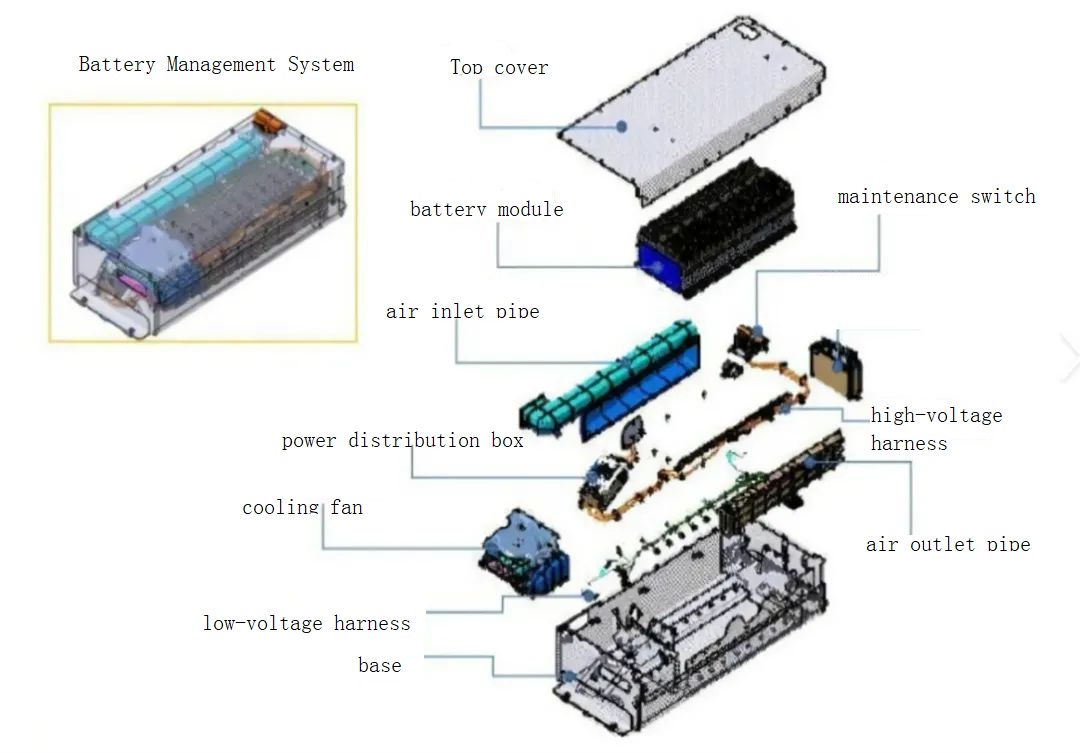

Uhlelo Lokuphathwa Kwebhethri le-BMS lusetshenziswa kakhulu ekuphatheni nasekulungiseni amayunithi ebhethri ngobuhlakani, ukuvimbela ukushaja ngokweqile kanye nokukhipha ngokweqile kwamabhethri, ukwandisa impilo yebhethri, kanye nokuqapha isimo sebhethri.

2.Izingxenye ze-BMS

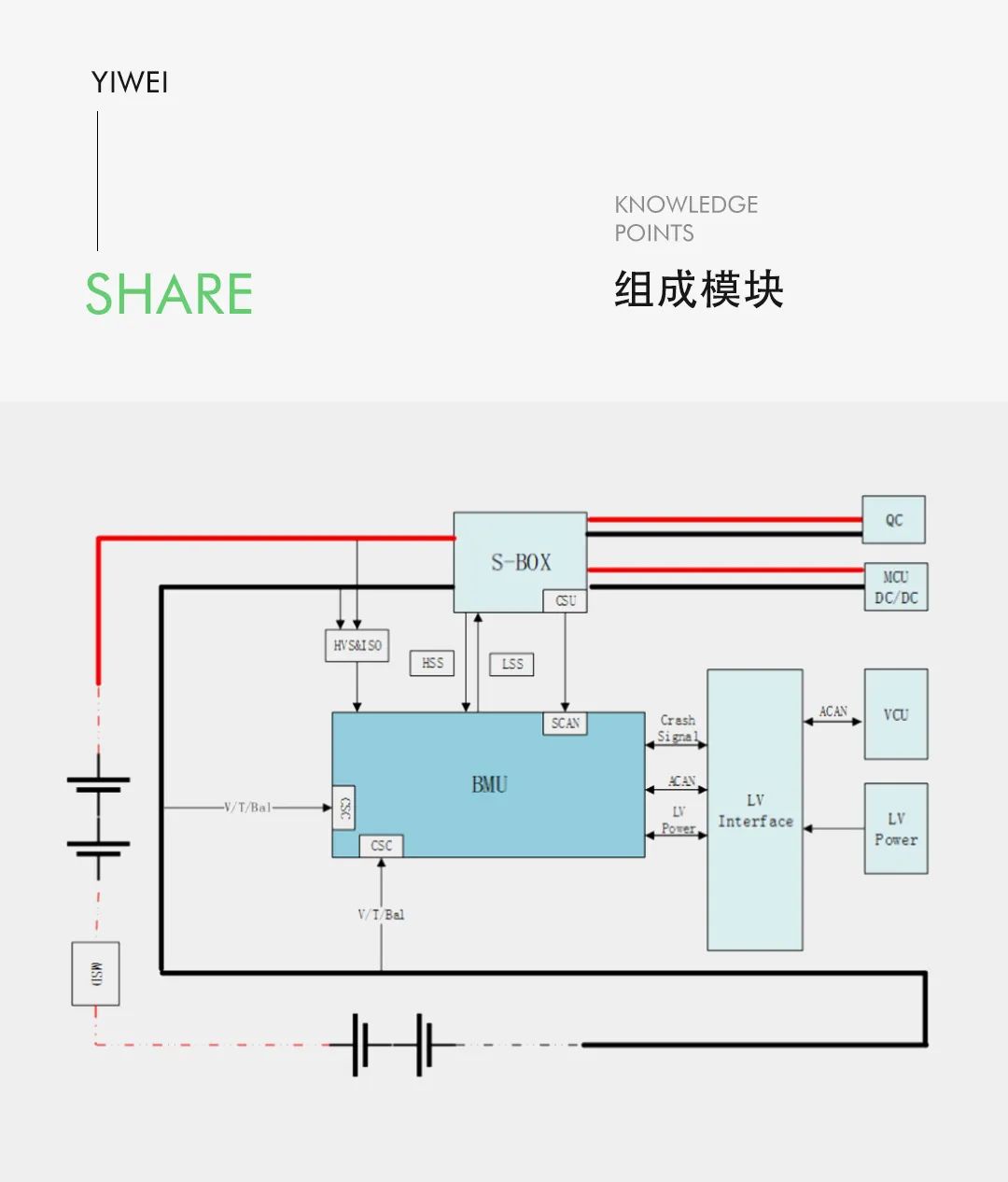

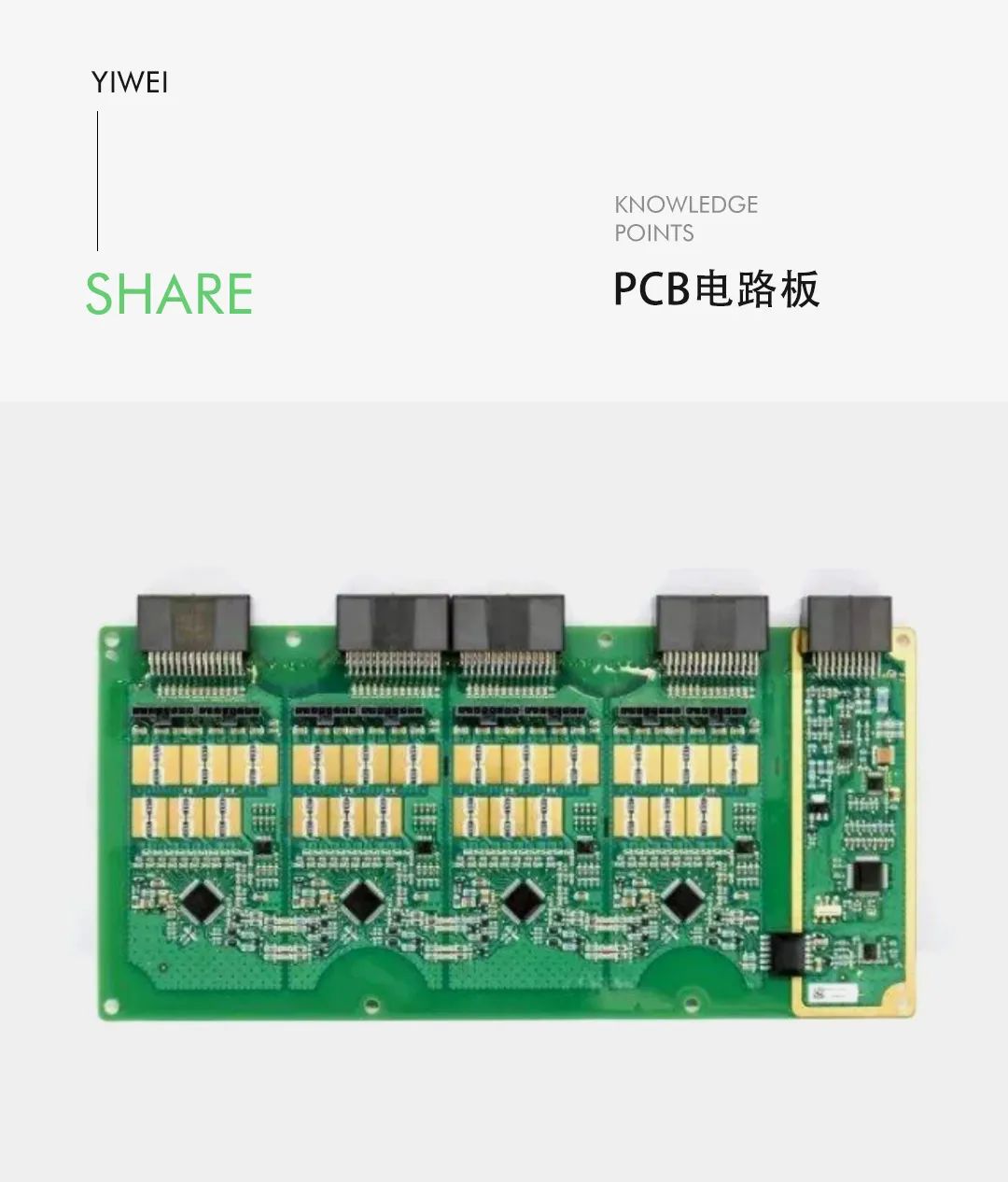

I-BMS yakhiwe kakhulu yi-BMU master controller, i-CSC sub-controller, i-CSU balancing module, i-HVU high-voltage controller, i-BTU battery status indicator unit, kanye ne-GPS communication module.

3. Uhlobo lomjikelezo wokuphila lwe-BMS

IbhethriUhlelo Lokuphatha (i-BMS) luyingxenye ebalulekile yezimoto zikagesi nezinye izinhlelo zokusebenza zamabhethri. Lunesibopho sokuqapha nokulawula isimo sebhethri ukuqinisekisa ukusebenza okuphephile nokusebenza kahle. Umjikelezo wokuphila webhethriI-BMSingahlukaniswa ngezigaba eziningana:

- Isigaba sokuklama: Ngesikhathi sesigaba sokuklama se-BMS, umsebenzi kanye nokucushwa kwe-BMS kumele kunqunywe ngokusekelwe ezicini ezifana nohlobo lwebhethri, isimo sohlelo lokusebenza, kanyeizidingo zokusebenzaLesi sigaba sidinga ucwaningo olunzulu kanye nokuhlolwa ukuqinisekisa ukuthiUmklamo we-BMSihlangabezana nezidingo zohlelo lokusebenza lwebhethri.

- Isigaba Sokukhiqiza: Ngesikhathi sesigaba sokukhiqiza se-BMS, izingxenye ezahlukene ze-BMS kumele zikhiqizwe ngokwezidingo zokuklama futhi zihlanganiswe futhi zihlolwe. Lesi sigaba sidinga ukulawulwa kwekhwalithi okuqinile ukuqinisekisa ukuthi ikhwalithi nokusebenza kwe-BMS kuhlangabezana nezidingo zokuklama.

- Isigaba sokufaka nokulungisa amaphutha: NgesikhathiUkufakwa kwe-BMSfuthiisigaba sokulungisa amaphutha, i-BMS kumele ifakwe ohlelweni lwebhethri futhi ihlolwe futhi ilungiswe. Lesi sigaba sidinga ukucophelela okukhulu nokunemba ukuqinisekisa ukuthi ukufakwa nokulungiswa kwe-BMS akulimazi ibhethri noma kuthinte ukusebenza kwayo.

- Isigaba sokusebenza nokulungisa: Ngesikhathi sesigaba sokusebenza nokulungisa se-BMS, ukuhlolwa nokulungisa okuvamile kumele kwenziwe ukuqinisekisa ukusebenza okuvamile nokusebenza kwe-BMS. Lesi sigaba sidinga ukuqoshwa kwedatha nokuhlaziywa ukuze kutholakale futhi kuxazululwe izinkinga ngokushesha futhi kuthuthukiswe futhi kugcinwe i-BMS.

- Umhlalaphansifuthiisigaba sokuvuselela: Ngesikhathi sokuthatha umhlalaphansi kanye nokuvuselelwa kwe-BMS, i-BMS kumele ibuyekezwe noma ishintshwe ngokusekelwe esikhathini sokuphila kwebhethri kanye nezidingo zokusebenza. Lesi sigaba sidingaukuhlaziywa kwedathakanye nokuhlola ukuze kunqunywe ukuthi i-BMS idinga ukuvuselelwa noma ukushintshwa nokuthi ingayibuyekeza noma iyishintsha kanjani i-BMS.

4.Imisebenzi yesofthiwe eyinhloko ye-BMS

Umsebenzi wokulinganisa

(1) Ukulinganisa ulwazi oluyisisekelo: ukuqapha i-voltage yebhethri, isignali yamanje, kanye nokushisa kwephakethe lebhethri. Umsebenzi oyisisekelo kakhulu wohlelo lokuphatha ibhethri ukukala i-voltage, i-current, kanye nokushisa kwamaseli ebhethri, okuyisisekelo sazo zonke izibalo zezinga eliphezulu kanye nomqondo wokulawula wohlelo lokuphatha ibhethri.

(2) Ukutholwa kokumelana nokushisa: Lonke uhlelo lwebhethri kanye nohlelo olunamandla aphezulu kudingeka luhlolwe ukuthi luvikela ukushisa yisistimu yokuphatha ibhethri.

(3) Ukutholwa kwe-interlock ye-high-voltage (HVIL): okusetshenziselwa ukuqinisekisa ubuqotho besistimu yonke ye-high-voltage. Uma ubuqotho besekethe yesistimu ye-high-voltage bonakalisiwe, izinyathelo zokuphepha ziyasetshenziswa.

Umsebenzi wokulinganisa

(1) Ukulinganisa kwe-SOC kanye ne-SOH: ingxenye eyinhloko nenzima kakhulu

(2) Ukulinganisela: lungisa ukungalingani kwe-SOC x umthamo phakathi kwama-monomers ngesekethe yokulinganisela.

(3) Umkhawulo wamandla ebhethri: amandla okufaka nawokukhipha ebhethri anqunyelwe emazingeni okushisa ahlukene e-SOC.

Eminye imisebenzi

(1) Ukulawula i-relay: kufaka phakathi i-main +, i-main-, i-charging relay +, i-charging relay -, i-pre-charging relay

(2) Ukulawula ukushisa

(3) Umsebenzi wokuxhumana

(4) Ukuxilongwa kwephutha kanye ne-alamu

(5) Ukusebenza okubekezelela amaphutha

Xhumana nathi:

yanjing@1vtruck.com +(86)13921093681

duanqianyun@1vtruck.com +(86)13060058315

liyan@1vtruck.com +(86)18200390258

Isikhathi sokuthunyelwe: Meyi-08-2023